Finished bonded components can be located in essentially any type of metal product that you can spot in day-to-day life. It's utilized in pipe-making, ductwork, automotive production, bike-making, steel-building, and extra. Unique band saws for cutting steel have set blades and feed systems for also reducing. Abrasive cut-off saws, likewise called chop saws, resemble miter saws however have a steel-cutting abrasive disks. Quickly accessibility valuable industry sources currently with complete access to the digital edition of The Fabricator en Español. Easily accessibility valuable industry sources currently with complete accessibility to the digital version of The Tube and Pipeline Journal.

Our Fabrication Drivers: Quality And Uniformity

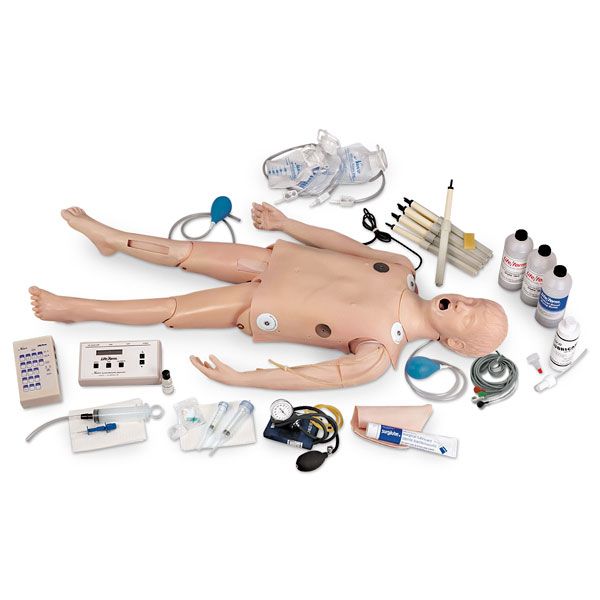

These materials for sheet metal manufacture normally can be found in determines with 0.006 ″ to 0.75 ″ (0.015 to 1.905 cm) density. In this checklist, you have actually run into prominent cpr manikin kinds of metal manufacture like spreading, forging, metal stamping, cutting, extrusion, and welding. As stated in the past, these approaches are used for crafting various metal components that are utilized in a variety of applications. They're also excellent for customized components that can match the choices of the end-user. Steel fabricators generally deal with a range of raw materials that might include different types of steel such as plate metal, expanded metal, welding cords and rods, and cast metal. Basically, manufacture is a critical action in creating any type of kind of finished steel component or framework.

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year - New Orleans CityBusiness

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year.

Posted: Tue, 07 May 2024 19:37:10 GMT [source]

Commercial Paint

The health issue arising from unpleasant blasting straight relates to the materials utilized at the same time. The dirts from the blasting material in addition to the blown up item can be extremely poisonous if breathed in. OSHA has a number of guidelines in place to shield the health and well-being of welders and cutters. Besides individual protective devices, OSHA suggests engineered controls that accumulate dirt, smoke and fume at resource.

Aluminum:

The capacity of these firms to make modern financial investments that enable them to preserve a variable outcome is the vital to maintaining consumer diversification. Metal construction industry has broad applications throughout an excellent lots of industries and consumer products. Criterion basic materials used consist of plate steel, installations, spreadings, formed and increased steel, sectional steel, flat metal, and welding wire.

The factory evaluate the schematic, calculate the expense of manufacturing and reply with both price and preparation. People have been extracting and machining steel for the previous 10 millennia, as evidenced by a copper pendant archaeologists found in northern Iraq that dates back to concerning 9,000 BCE. Manufacture shops as we know them today began to exist around the Industrial Revolution, when sheet steel remained in much greater need than before. The development of the hydraulic press, which allowed manufacturers to apply unmatched stress to pieces of metal, transformed the steel construction sector.

Since architectural steel is carbon steel, it has approximately 2.1% carbon by weight. High-strength and low-ductility products are produced when the carbon material of steel is raised. The necessary carbon quantity or web content will depend upon exactly how the steel will certainly be utilized. The safety and quality standards for producing architectural steel differ by local and national criteria.

Just like various other producing procedures, both human labor and automation are generally used. A made item might be called a manufacture, and shops specializing in this sort of work are called fabulous shops. Metal manufacture is the procedure of building machines and structures from raw metal products. The procedure includes cutting, shedding, welding, machining, creating, and assembly to develop the end product.

Machining is a subtractive shaping process that gets rid of undesirable material to create a kind. Casting is commonly approved as the best process for mass-produced items where the exact same mold and mildew can be used over and over again with marginal difference in the final result. MIG, steel inert gas welding, makes use of a mechanism including a strong cord electrode that creates an arc in between this electrode and the product being worked, and the components are after that fused with each other. We take every step feasible to ensure the lowest price with the best quality.

In addition, this is an excellent material for welding because of the product's ease of bending. Therefore, stainless-steel is regularly utilized in applications needing rust resistance. Milling gets rid of extra product from a raw metal part utilizing specialized multi-point cutting tools. This procedure can be carried out by hand or with the help of a CNC milling machine. Milling, generally, is a lot more often employed as an additional metal fabrication treatment. This step focuses on confirming if all layout specs are fulfilled during the metal item fabrication.

Easily accessibility valuable market resources currently with full access to the digital edition of The Welder. Conveniently gain access to valuable market resources now with full accessibility to the electronic version of The Producer. With numerous presses and bending tools and a wide variety of tooling we can flex almost any part and account. Spray painting also consists of poisonous steels and chemicals that pose additional health issues when breathed in.